Environmentally conscious customers love the REHANCE process we provide on all our t-shirts. It’s a higher quality, eco-friendly alternative to traditional t-shirt printing methods, and it’s unique to TS Designs.

Let’s talk shop for a minute.

Traditional Printing – Not So Environmentally Conscious

There are two main formats of screen printing ink – plastisol and water based. A typical screen printer will take a dyed shirt (which is to say, a shirt that’s already a color) and print it with plastisol inks.

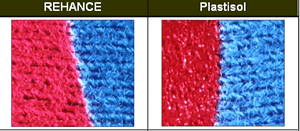

Plastisol inks are all-around nasty. They create a surface coating on the shirt that feels like plastic (surprise!) and leave the fabric covered with an uncomfortable, rubbery print that will eventually crack and peel off the shirt.

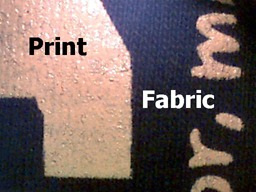

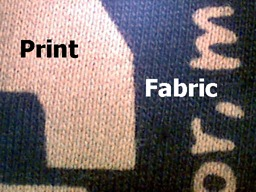

Pictured: A tactile print at 10X magnification. Tactile inks—the choice of most screen printers—use a plastic coating to cover the surface of the fabric with a design. This is a less expensive option, but results in a print that can peel and chip away over time.

These inks also almost always contain PVC and phthalates; the former emits dioxins (a very potent environmental toxin/pollutant) during manufacture/disposal, and the latter are known to cause various negative health effects.

Water based inks, on the other hand, soak into and become part of the shirt. They’re more permanent; will never crack, peel, or fade; and leave the fabric completely breathable. They also contain no PVC or phthalates.

Most traditional printing is performed with plastisol.

So why is most printing performed with plastisol over water based inks? Because in order to print a light color on a dark shirt, a surface coating must be used.

So while water based inks feel better and are more environmentally-friendly, they don’t work well on color shirts. On the other hand, plastisol is less comfortable and harsher to the environment but easier to work with and more versatile.

A Bold Solution – REHANCE

REHANCE is the solution to this problem.

The REHANCE process uses a specially-formulated water based ink that resists dye, which means we print white shirts and then dye them a color (rather than printing on a shirt that’s already a color).

We take white shirts, print them with the REHANCE chemistry, and then garment dye the shirts black. The printed ink seals the area it’s printed on and prevents the color from dyeing or staining that area. As a result, a white print is visible on the shirt. However, this white print is not a surface coating – it’s simply the lack of black dye.

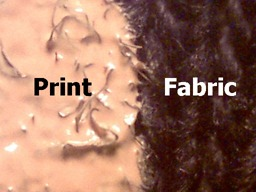

Pictured: REHANCE print at 10X magnification. REHANCE allows us to print water based inks on a dark t-shirt, something difficult for other printers to accomplish without harsh chemicals. Our inks become part of the shirt, rather than sitting on top of it, resulting in a print you can’t feel, and won’t crack, peel or fade over time. It’s more expensive than tactile inks, but provides superior durability.

Think of it as using painter’s tape before painting a wall. Tape over the area you don’t want to paint, then peel the tape off afterward and voila! No color. REHANCE essentially works the same way, except there’s nothing to peel off afterward.

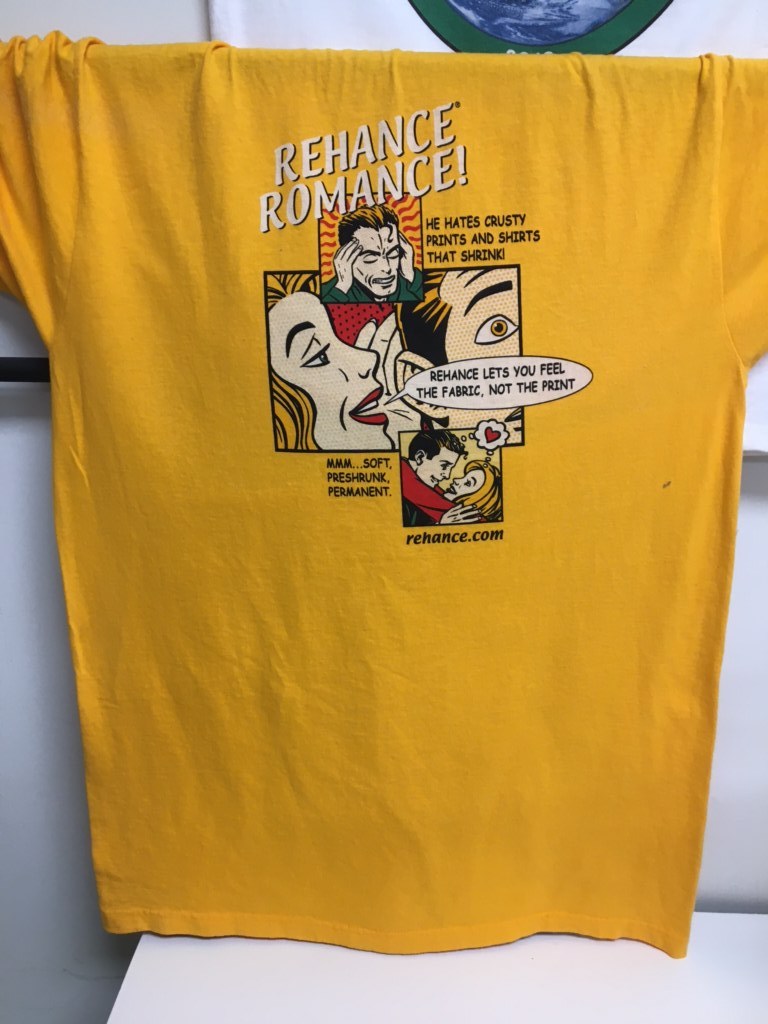

Learn more about our wholesale t-shirt options so you can have your own Rehance Romance here.