Econ 101 Should Drive Energy Debate

Originally printed in The Charlotte Observer on August 1st.

Last week I joined 6 fellow NC citizens in DC to convince our senators to pass a comprehensive energy bill. As you can probably guess, those who support it welcomed us, and those who don’t listened with glazed expressions.

Our group of six represented not only a wide geographical area of our state, but also diverse perspectives. We were a retired veteran who served in the Iraq War, two executives of a large solar finance/installation company, two directors from the NC Wildlife Federation, and me: a small manufacturing business owner. My particular outlook comes from operating a local manufacturing business, TS Designs. NAFTA taught us the importance of local sourcing, which is why over 90% of our products are made in the US, 70% right here in NC. For the same reason, we also understand the importance of taking control of our own energy sources, which is why we have been making biodiesel from local waste vegetable oil for over 7 years, and installed two solar arrays and a wind turbine at our facility.

Richard Nixon was the first president to call for the reduction of our dependence on foreign oil, and every president since has echoed his sentiment. Even so, we now import well over 50% of the oil we consume here in the states. That’s over $1 billion per day sent to countries controlled by unstable, hostile regimes that don’t share our values and are at odds with our interests. While in DC, I had the chilling experience of hearing from a retired general and an Iraq War veteran who experienced American soldiers killed by weapons likely funded by US dollars.

Each day the senate delays on a comprehensive energy plan that focuses on non-petroleum-based fuels, our enemies are enriched. Now is the time for bold action. Many say the solution is to drill here. For the moment, ignore any argument you’ve heard about climate change and environmental damage and simply consider this: we consume 25% of the world’s oil, but at most have access to only 2% of the world’s remaining supply. Economics 101 testifies that as we drain that supply, prices will only continue to increase unless we lower demand.

The best way to enact change in a capitalist society is by voting with your dollar. But there are simply no currently viable alternatives to petroleum-based fuels on the market to vote for, and corporations only have one responsibility: to maximize value for their shareholders, not to look out for the long-term welfare of the American People.

No matter how involved you believe the government should be in our lives, most people agree on one thing: the government is responsible for defending Americans from enemies, both foreign and domestic. Our demand for foreign oil is a direct security threat to our country. We need Congress to lay the groundwork for a sustainable energy future for America and let the market take over from there.

by Eric Henry and Eric Michel

The Golden Girl

We may be the only North Carolina-based “dirt to earth” t-shirt company whose number one priority is sustainability, but we’re not the only ones getting creative with the way we do responsible business.

AuH2O, or Goldwater, as the elemental compound is spelled out, is a clothing company located in New York, New York’s East Village. Kate Goldwater, owner and designer, opened up shop in May of 2006, fresh out of college. What makes her blog-worthy you ask? Take a closer look at her high fashion creations and you will find that they are recycled; 100% original in every way, utilizing clothes that were once damaged, out of style, or just plain old. Ranging from combination t-shirt/buttondowns for the gentlemen to risque miniskirts for the ladies, AuH2O’s innovations transcend a lot of peoples’ misconceptions about what should be done with your favorite shirt once that hole in the armpit becomes socially unacceptable. Don’t you dare throw that away. Create!

Check out Ms. Goldwater’s site for some inspiration: http://www.auh2odesigns.com.

And you can buy directly from the source on Etsy (an amazing little site where vintage & handmade goods can be bought & sold): http://www.etsy.com/shop/auh2odesigns.

For those of us who like to Do It Ourselves, I would highly recommend paying a visit to threadbanger.com for step by step tutorials on limitless possibilities for reusing those recyclables.

Take it from me, the starving artist, whose dorm room curtains were once made out of cut up tees and whose feet often tread upon a pair of handmade duct tape flip flops. (Hey, it’s a conversation piece.)

Peace, love & t-shirts,

Natalie

A Whopper from Your Neighborhood Burger King isn’t Quite what we Mean by Local…

On my first tour of TS Designs, I was immediately impressed by each and every sustainable innovation on the premises. One of my absolute favorite features, however, is the Garden of Eat’n. This extensive employee-grown garden provides veggies for those of us who spend a few hours per week hoeing, watering, and loving the plants. It is just one more aspect of TS Designs that makes us so incredibly unique. We not only are all about making the very best t-shirt around, but we plug sustainability into all facets of our lives… our faces being one of those extremely important facets.

“Buying local” has been one of the latest pushes in the Green Movement. As Eric Henry (our beloved President of TS Designs) once said, “Just because you bought that cheeseburger from the McDonald’s down the street from your house does not mean you are buying local.” Unfortunately, some people still fail to make the distinction between products that are “final destination local” and “of local origin”.

I am personally a grocery snob. There, I said it. During the school year, I carpool with my other hippie friends once a month to drive from Elon, NC to Chapel Hill, NC (a forty minute hop, skip, and a jump away) to hit up our nearest Trader Joe’s. They supply fantastic organic, antibiotic-free, grass-fed, crunchy granola groceries from peanut butter to soy nuggets. I love Trader Joe’s. However, with summer in full swing, I’ve been looking to farmer’s markets for my produce runs.

But buyer beware! Ask the vendors where their goods are from. It’s very easy to strike up a conversation with a overall-bedecked fellow peddling tomatoes, “Hey there, these tomatoes look lovely, do you grow all of these yourself?” And you will be met with one of two answers, “Why yes I do,” or “Nope, just shipped these bad boys in from Mexico.” Having been to a Burlington, NC farmer’s market and receiving the latter of the two responses, I make certain I know exactly what I’m buying, and where it came from.

By becoming a conscientious consumer, you are not only keeping yourself informed of what you’re putting in your body, but also knowing exactly where your dollar is going. Buying local supports the local economy, your local growers, and your overall well-being. Not sure where to start your journey to becoming a better buyer in North Carolina? Keep reading.

SAXAPAHAW RIVER MILL

http://www.rivermillvillage.com/farmers.html

A quaint little town filled with history, fantastic people, and even better food. On Saturday afternoons, Saxapahaw boasts an incredible Market & Music Series, bringing the best organic goods, crafts, and musical talent to one riverside hill. Bring your blanket and an empty cooler for an amazing picnic to be contributed to by the Saxapahaw vendors. Don’t forget to stop by the general store! (I highly recommend the goat burger.)

GROWING SMALL FARMS: North Carolina Cooperative Extension

http://www.ces.ncsu.edu/chatham/ag/SustAg/otherareamarkets.html

This resource contains a plethora of excellent locations all over the Triangle Area to find the farmers market nearest you. I have explored several of the markets on the list, however my favorite thus far is the Downtown Raleigh site in terms of convenience for me.

WHY BE THE VILLAGE IDIOT WHEN YOU CAN BE A LOCAL HERO?

Peace, love & t-shirts,

Natalie

Elon’s Fusion of Art & Earth

This fall, the Art Department of our local liberal arts college, Elon University, will be working to add an Eco-Art course to its repertoire. A small student research team, led by Professor Samantha DiRosa, aims to create a brand new curriculum set to be introduced in the 2011 spring semester. The class will be centered on the rapid rise in the sustainability movement and its emergent impact on the art world.

This isn’t a tree-hugging, crunchy granola meeting for the exclusive Birkenstock-donning population of the University’s campus. DiRosa and her team want to involve everyone, from the engineers to the biologists and from the sociologists to the journalists. The combination of scientific inquiry and artistic creativity opens up a brand new channel for discovery in both the arts and the sciences. Collaborating teams of students in this course will get a chance to critically address and resolve issues in our community with the implementation of their original sustainable artistic solutions.

Science geeks, meet the art freaks. Now go save the world.

…

If you’re wondering who this new mystery contributor to the TS Designs Blog is, I’m Natalie Saragusa. I’ve recently come on board to this amazing company as an intern for my senior year at Elon University. People and the planet are two of my greatest passions in life. I’ve been after this position for months now, and finally get to be a part of the company that can successfully incorporate both of those aspects into its business. I am a digital art major at Elon, with a particular interest in printing, graphic design, and fashion. Looks like I found the perfect niche here, huh?

I look forward to sharing TS Design’s amazing story and all that a more sustainable world has to offer with you, bloggers! Stay tuned.

PEACE LOVE & T-SHIRTS,

Natalie

Raising the Bar

A few years ago, we looked at the production chain of a printed t-shirt and separated its impact into 3 categories:

- Where the shirts were made

- What the shirts were made of

- How they were printed

We’re always striving to push the envelope of sustainability with each of these impacts. But addressing every one certainly gets expensive, so we always encourage our customers to address what they can afford, and push to continuously improve the footprint of their shirts.

For over a year now, TSD has been committed to only processing orders that meet at least one of the following criteria:

- Made in the US

- Made out of a sustainable fiber

- Printed with low-impact water-based or other PVC/phthalate-free inks

We’re not in this to be the only sustainability-minded printer. We want to raise the bar in our industry, and the best way to do that in a capitalist society is demand. If you’re buying t-shirts, whether you buy from TSD or not, consider committing to a process of continuous improvement for your products. The more demand for a more sustainable product, the more the industry will convert to a more sustainable model.

REHANCE: The Director’s Cut

The REHANCE process is a more environmentally-friendly, higher quality alternative to traditional t-shirt printing methods. Before explaining how REHANCE works, it would be helpful to review how the vast majority of textile printing is accomplished.

Traditional Printing

There are two main formats of screenprinting ink – plastisol and waterbased. A typical screenprinter will take a dyed shirt (which is to say, a shirt that is already a color) and print it with plastisol inks. Plastisol inks are all-around nasty. They create a surface coating on the shirt that feels like plastic (surprise!) leaving the fabric covered with an uncomfortable, rubbery print that will eventually crack and peel off the shirt.

These inks also almost always contain PVC and phthalates; the former emits dioxins (a very potent environmental toxin/pollutant) during manufacture/disposal and the latter are known to cause various negative health effects.

Waterbased inks, on the other hand, soak into and become part of the shirt. They are more permanent, will never crack, peel, or fade, and leave the fabric completely breathable. They also contain no PVC or phthalates.

So why is most printing performed with plastisol over waterbased inks? Because in order to print a light color on a dark shirt, a surface coating must be used.

Analogously, consider watercolor paint vs. latex paint. If you have a black piece of paper and try to paint a light blue watercolor paint on it, the result is less than impressive. The paint will soak into the paper, but since the paint is translucent and does not sit on top of the paper, no color is perceived.

On the other hand, if you paint that piece of paper with latex paint, a paint that is opaque and will sit on the surface of the paper, the color will be bright and vibrant. But you’ll also be able to feel that surface coating, and could chip it away with your fingernail if you tried. This is essentially the same difference between waterbased and plastisol inks.

So while waterbased inks feel better and are more environmentally-friendly, they don’t work well on color shirts. On the other hand, plastisol is less comfortable and harsher to the environment, but easier to work with and more versatile.

REHANCE is the solution to this problem.

The Solution

The REHANCE process utilizes a specially-formulated waterbased ink that resists dye, which means we must print white shirts and then dye them a color (rather than printing on a shirt that is already a color).

Using our example above, we would take white shirts, print them with the REHANCE chemistry, and then garment dye the shirts black. The printed ink will essentially ‘seal’ the area it’s printed on and prevent the color from dyeing or staining that area. As a result, a white print is visible on the shirt. However, this white print is not a surface coating – it is simply the lack of black dye.

Think of it as using painters tape before painting a wall. Tape over the area you don’t want to paint, then peel the tape off afterward and voila! No color. REHANCE essentially works the same way, except there’s nothing to peel off afterward.

The Specifics

Reactive dyes chemically attach to cellulosic compounds (e.g. cotton) on the molecular level by creating a covalent bond between the dye molecule and the hydroxyl groups of the cellulose molecule. On the wild off-chance that you have no idea what that means, I’ll explain in a bit more detail.

When I say “hydroxyl groups,” I’m referring to a single oxygen atom bonded to a single hydrogen atom. In the diagram below of a cotton molecule, the hydroxyl groups are everywhere you see OH.

During the dye process, reactive dyes will bond to these hydroxyl groups to create a permanent color on the shirt. The chemist who developed REHANCE refers to these hydroxyl groups as “dye sites.” The REHANCE chemistry bonds to those hydroxyl groups before the dyes have a chance to. Take away the dye sites in a printed pattern, and no color will bond to the areas printed.

Even Better

So what I’ve just described allows us to achieve a white print on a dark shirt without using a surface coating. But what if I want, say, a light blue print on a dark shirt? Never fear! The REHANCE chemistry can be printed over a waterbased ink to protect that ink from the color the shirt will eventually be dyed. So first: print ink color, second: print REHANCE over ink color. From there, it works exactly the same way as described above, except that the fabric has an ink printed on it before the REHANCE chemistry bonds to the dye sites.

If you’re asking yourself “How can ink be printed in the same place as the REHANCE chemistry and they don’t conflict with each other?” then worry not, for I will make all things clear. Inks, unlike dyes, are affixed to cotton in a completely different way. Normal inks do not bind to hydroxyl groups, so there is no conflict among the inks and REHANCE chemistry for dye sites.

Advantages

No PVC; no phthalates; no cracking, fading, or peeling; no petroleum products; no rubbery, sticky print across your chest. Just a completely breathable, permanent, colorful print. You could even iron the shirt if you were so inclined (though why anyone would iron a t-shirt is beyond me).

It’s also worth noting that REHANCE printing leaves less stuff on the shirt in general. REHANCE works by stopping stuff from being put on the shirt, whereas plastisol printing adds stuff (ink) on top of the shirt to cover up even more stuff (dye).

Not Discharge

For those familiar with textile printing, it’s important to know that REHANCE is not discharge. Discharge works by taking an already-dyed shirt and printing zinc formaldehyde sulfoxylate to blast that dye out of the shirt. Rather than our method, which prevents dye from bonding to the shirt in the first place, discharge uses harsh chemicals to eliminate the color after it’s already affixed to the cotton.

Learn More

REHANCE is the technology that allows us to stop dye from sticking to fabric in a targeted manner. To learn more about the waterbased inks we use to print the design colors, check out this page.

More Local than Local

Everyone loves local, but it’s easy to get confused about what local means, and how best to obtain local products. Read on to learn about how TSD offers a truly local product.

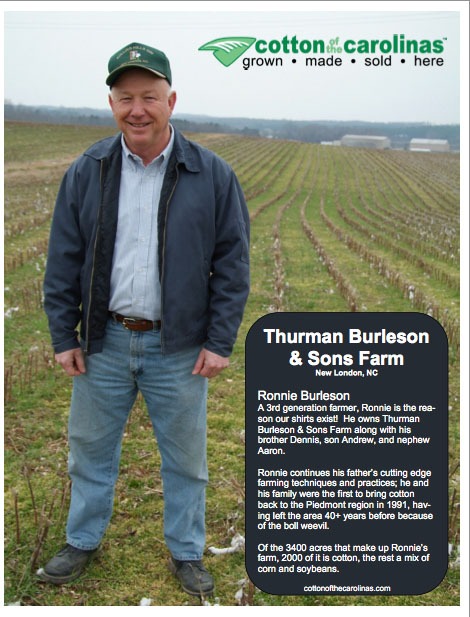

Cotton of the Carolinas at BALLE

In May 2010, Eric Henry, along with Cotton of the Carolinas supply chain members Brian Morrell and Ronnie Burleson, rocked the house at the BALLE Conference in Charleston, SC. Click here to check out the video of their presentation!

Why chickens at a company that prints t-shirts?

Eric Henry and Tom Sineath with one of the newest additions to TS Designs

(From Eric Henry, TS Designs president)

I have been talking about getting chickens at TS Designs for over a year, well on April 5th we got 7 of them. Why chickens at a company that prints t-shirts? A couple of things I have learned on journey to be a more sustainable company, there is no clear path to get there and you have to be the one to take the lead if you want to see positive change. We started growing veggies at TS Designs a couple of years ago to give our employees access to local, healthy food, inexpensively. One of the negatives you hear about the local, organic food movement, is that it is only for the higher income folks. We think company gardens can help fill that gap by giving employees access to this food. We are able to take advantage of the space that most companies plant grass on and spend the summer mowing. I have found that chickens can be a key to successful gardening and a very cheap source of protein, via eggs, for our employees.

Chickens give back to the soil what the plants take out. We have created a chicken area inside the garden area. We picked a couple of rows that we are not planning to plant in the next 6-12 weeks and use a solar powered electric fence to keep the chickens out of the rest of the garden. While the chickens are in these rows they scratch and peck out bugs and worms, which aerates the soil along with depositing some great fertilizer. I am excited about testing out using our organic cotton scraps as the nesting material. We just redesigned the compost pile that is set right outside of the garden. I am hoping the chicken manure will help break down the cotton scraps faster, which will come back into the garden as great compost. So next time you are in the area to buy some of our great t-shirts walk around the corner of our building and introduce yourself to our 7 latest TS employees.

Dow Corning is testing their silicone inks at TS Designs

Here at TS Designs, we are currently working on a project with Dow Corning to test their silicone inks in automatic printing. We at TS Designs want to support anyone who is interested in developing more environmentally friendly products and we’re excited to contribute to the development of a cutting-edge environmentally-friendly printing technology. We are interested in anything with an environmental story and Dow Corning came to us because they knew we would have an open mind. The silicone inks have similar properties to plastisol inks, but they are a much more environmentally friendly option because they do not contain PVCs or phthalates (both of which have harmful effects when they are washed into the water supply and become a part of the ecosystem).

Dow Corning, a multinational corporation specializing in silicone-based technologies came to us because of our close proximity to their location in Greensboro, NC, as well as our environmental interests. We rented them the equipment in our facility as well a production employee so that they could test the inks in a multi print, production environment.

So far, they have completed one day of trials, and we anticipate that there will be more to come in the future as they continue to develop their inks.

Cold wash, line-dry

Here at TS Designs we are all about sustainability. We focus on sustainability in our product, our business practices, and our final impact on the environment. However, there is only so much we can do, the rest of the environmental choices are up to the consumer. In a 2007 report commissioned by the Danish EPA, an environmental assessment was conducted on six textile products—one of those was the cotton t-shirt.

The report concluded that it is the consumer of the product that ultimately has the greatest impact on the environment—first by choosing an organic product, and then by washing as little as possible, drip-drying, and not ironing.

So if you have ever wondered what you can do for the environment, you can make informed decisions on how you launder your t-shirts. Here at TS Designs, we recommend you wash your clothes with cold water using environmentally friendly detergents and line-dry. According to the study, the consumer can reduce primary energy consumption by 70 percent by not tumble-drying. It is also important to simply wash less. The study concluded that by halving the amount of times you wash your t-shirt increases the life of the t-shirt by 50%.

If you want to reduce your impact, wear your t-shirt more than once before washing it and limit your use of your clothes dryer. Eric Henry, president of TS Designs said, “We are making a sustainable product, but the consumer in the long run has the greatest influence on the impact to the environment on how they care and dispose of it.”

To read the full report, click here.

T-shirt Design Contest

Want to see your design on a TS Designs shirt? Now you can! We are having a T-shirt design contest. There will be 3 winners, 1 for each of our different brands (tsdOrganic, tsdRecycled, or tsdCarolinas). The prize is $100 and your design on shirts all over the country. The deadline is Feb. 28.

A note from our President, Eric Henry

Good morning, I am Eric Henry, President of TS Designs based in Burlington, NC.

Since NAFTA we have lost over 100,000 textile and apparel jobs in North Carolina.

At TS Designs we want to be a different company, a company based on a triple bottom line of People, Planet and Profit. We print t-shirts, 90% of them are domestically made and 60% are made in North Carolina.

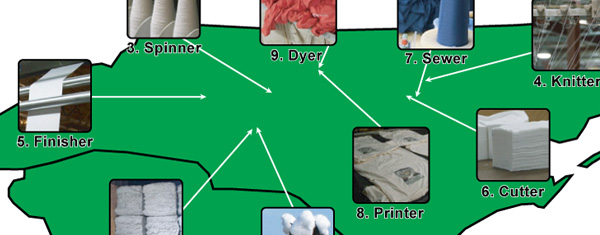

North Carolina is the 4th largest grower of cotton in the US and we export 50% of that cotton, so last year we launched a new brand, Cotton of the Carolinas. The Cotton of the Carolinas shirt is grown, made, and sold entirely in North Carolina. Our t-shirts impacts 700 jobs in North Carolina at 6 different companies. We go from dirt to shirt in 750 miles when an average t-shirt can travel 17,000 miles!

It is the only apparel line that is completely transparent for the consumer all the way to the farmer. When you get one of our shirts you can connect directly to Ronnie Burleson, the cotton farmer, and the other 5 companies that are involved in making this t-shirt.

Our t-shirts do cost more, but hopefully one thing that we have learned from this record unemployment in a jobless recovery is that there is more than just low price.

For more information about Cotton of the Carolinas, go to the website. cottonofthecarolinas.com

Reconnecting to local food through the community garden

Both Tom Sineath and Eric Henry here at TS Designs are committed to reconnecting their employees back to local food. It is better for them, their wallets, and the environment. TSD will be moving ahead with their community garden this year after a successful first year under the management of Glenn Kern. Glenn will be returning, but there will be a lot of changes for this season. This year, instead of volunteering, all employees will be required to work a half hour a week in the garden—they will be paid for their time, of course.

TSD lost the hoop house during a recent windstorm (see photo above), but that opened the door to bring in chickens. Ben Wright from Peacehaven Community Garden and Will Hooker, head of the Permaculture program at NC State, will help with the chicken endeavor. The plan is to start with about six chickens, which will be allowed to graze in the fallow rolls of the garden, contained in a fence, within the fenced garden.

Tom is working on updates to our greenhouse (see photo above), which should be complete by the end of January. After taking a refresher course at the fall conference of Carolina Farm Stewardship in Black Mountain, Eric is planning to dive into heirloom tomatoes this year. Partnering with Weston Monroe from Peacehaven, they will start the seeds next month in the greenhouse.

There will also be other changes in the garden this year, including improvements to the watering system, putting in individually controlled soaker hoses for each row. The deer fence will also be improved. Last year there were continuous issues with sections coming down, deer never got into the garden, but it is just a matter of time if the problem is not corrected. It should be a bumper crop at TSD this summer, come by and have lunch with us!

TSD Carolinas Marketing Material

In an effort to help our customers differentiate Cotton of the Carolinas products from conventional shirts, we have created marketing materials for retailers selling CotC shirts. If you sell or distribute Cotton of the Carolinas shirts, please click on the links to download these materials and use them as you see fit.

This is a 8.5×11 sheet that profiles Ronnie, our cotton farmer.

This is a 1/3 page pamphlet that shows people how to track their shirt that can be cut into 3 pamphlets per page.