We had a very successful annual Cotton Harvest Tour last Saturday, October 24th down in New London, NC. It was a picture perfect North Carolina fall day, with blue skies and warm sunshine. Our morning started by welcoming a smiling group of guests outside of Rolling Hills Gin. Eric greeted the group and we made our way upstairs to the new “Cotton of the Carolinas” conference room in the gin offices.

The group session kicked off with introductions around the room, and Aeriel asked guests if they owned a #CotC t-shirt. Surprisingly, only about 1/3 of the group owned one of our t-shirts, but we’re hoping since Saturday, they’ve all ordered at least one from our online store! Next Eric gave an overview of TS Designs‘ history and explained how the Cotton of the Carolinas brand came about.

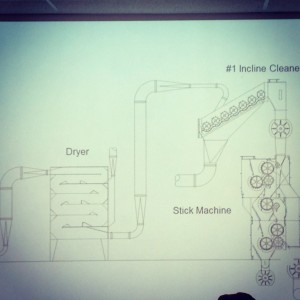

Next up, Wes Morgan, Manager of Rolling Hills Gin, gave great insight into what exactly the cotton ginning process is. He offered valuable info-graphics that detailed the many different pieces of machinery running in the gin. He also had a really cool slow motion video of several steps of the process. This allowed everyone to learn more about what they would later see up close downstairs in the gin operations area.

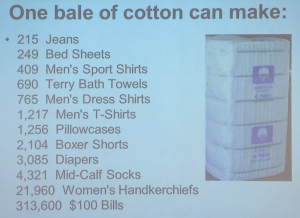

Wes shared many interesting facts throughout his presentation, but here’s a few if you missed them on Instagram/Facebook.

- The dryer at the start of the ginning process, dries the cotton in FOUR seconds!

- From a single bale of harvested cotton, the gin will typically yield about 500 lbs. of cotton and more than 600 lbs. of cotton seed; that’s more seed than cotton.

- What happens with all that cotton seed? The gin sells it to #NC dairy farmers to feed to their herds.

- And these too…

Once the guests were well-versed on ginning, we took about 30 minutes to tour the gin on foot. It’s an extremely loud mechanical environment, so all visitors are required to wear ear plugs, which made for an interesting setting to ask questions on the floor! The floor only had about 5 employees working at that time, because Wes and his team are great at innovation and consistently updating their programs/software/equipment to be as efficient as possible. The operation is largely automated, aside from a few steps, which calls for most employees to act as supervisors of the machines.

Next we all enjoyed delicious boxed lunches from our friends at Company Shops Market and the group spent time getting to know each other.

Once tummies were full, our favorite cotton farmer, Ronnie Burleson took the stage to share about his farming life, growing cotton, being a part of the #CotC supply chain and how his son is taking the reins as he gets older. The group loved hearing what Ronnie had to say, especially his story about how cotton made its come back in the 1980s.

The day rounded out with a visit to Ronnie’s cotton field, about 8 miles away from the gin. Ronnie’s son Andrew and his brother were running the two harvesters, and opened them up for ride alongs. Our tour-goers definitely took advantage of that opportunity, and spent quite some time rotating out for rides.

The machines are about 5 years old, and they’re the newer round balers. The cost about $750,000 and to run one for just one hour costs about $100, between fuel and manpower. They’re impressive pieces of equipment, but definitely make the cotton harvest process look different today than it did back in the early 1900s all the way up through the 1950s, when cotton was all picked by hand!

All in all the tour was a huge success and we couldn’t have asked for a more perfect day! Until next year, keep wearing cotton.